vickers hardness test material science|vickers hardness test procedure pdf : exporters Vickers hardness testing has been widely used as one of the basic and reliable . 6 de fev. de 2024 · The Pin Slot on the side of the desk requires — wait for it — a pin. But not just any old trinket will do, either; you’ll need to recover the Harp-Shaped Pin from .

{plog:ftitle_list}

Los calendarios que se publican anualmente son los siguient.

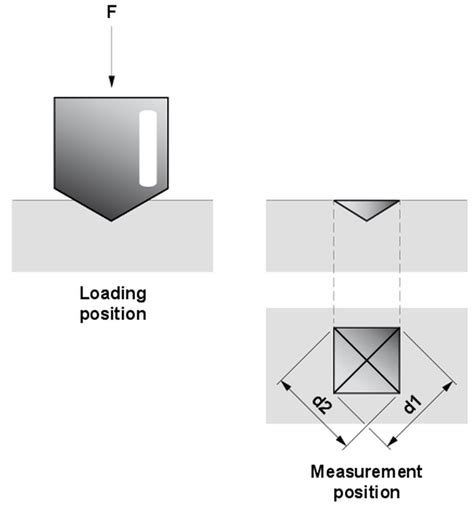

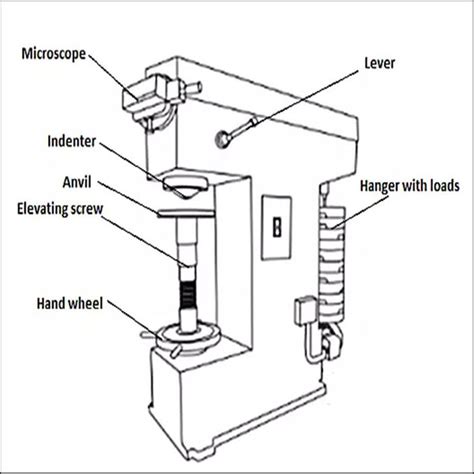

Vickers hardness of ground and polished material was determined at room temperature for a series of load (100–500 gms) using a Leitz Durimet and at high temperature for a load of 500 gms using a Nikon HT-5 microhardness tester.Vickers hardness testing has been widely used as one of the basic and reliable .In a Vickers hardness test, a pointed diamond pyramid with a square base is .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.

In material science, the Vickers hardness test stands out as an exceptionally reliable & flexible method for assessing the hardness of a diverse array of materials. This technique is crucial .The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers Hardness Test is a powerful tool in the realm of materials science and engineering. Its ability to accurately measure hardness across a broad spectrum of materials, its simplicity, and its repeatability have .In a Vickers hardness test, a pointed diamond pyramid with a square base is used as the indenter. The opposite faces of the pyramid have an included angle of 136°. This indenter is .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our . Forensics and Gemology: The Vickers test is employed in forensic science to determine the hardness of materials found at crime scenes. It is also used to assess the authenticity of gemstones.

vickers hardness test procedure pdf

Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area . Brinell hardness test (explained in this article) Vickers hardness test; Rockwell hardness test; Specially prepared specimens or real components can be used for hardness testing, provided that their functionality is not .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .

G. Sundararajan, M. Roy, in Encyclopedia of Materials: Science and Technology, 2001. 1.3. Vickers Hardness TestingIn a Vickers hardness test, a pointed diamond pyramid with a square base is used as the indenter. The opposite faces of the pyramid have an included angle of 136°.The Vickers hardness test is similar to the Brinell test. However, it uses a four-sided inverted diamond pyramid with an apex angle of 136°. The Vickers hardness number (HV) is the ratio of the impressed load to the square indented area. The Vickers hardness test is of particular value for hard, thin materials where hardness at a spot is required. Figure: Rockwell hardness test procedure. The actual test load F 1 is applied in addition to the preload and the indetor penetrates the material with the total force F=F 0 +F1. The test load to be set is taken from table books depending on . Vickers hardness values of test materials during exposure time of 20 and 40 s and depths of cure of 2 and 3 mm were determined and compared. . Department of Operative Dentistry and Science of Dental Materials at Dr. Ishrat-ul-Ebad Khan Institute of Oral Health Sciences, Dow University of Health Sciences and Material Engineering Department of .

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: . This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell hardness tests, .

MATERIAL SCIENCE AND ENGINEEERING LAB REPORT VICKERS HARDNESS TESTING NAME CLASS NUMBER MATRIC. MUHAMMAD AFFAN AKMAL BIN ABDUL RAHMAN. . The Vickers hardness test is easy to use and its benefits far outweight any potential disadvantages include during the experiment of hardness testing with any type of material to measure the .

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. . Brinell Hardness Test. See also: Vickers Hardness Test. See also: Knoop Hardness Test. References: Materials Science: U.S. Department of Energy, Material Science. DOE Fundamentals Handbook, Volume 1 and 2. January 1993. In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate material characterization and evaluation. With its wide range of applications in material science, manufacturing, and research, the .

ecu tester tool

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can also be used as a microhardness test method, mostly used for small parts, thin sections, or case depth work. Since the test . The Vickers Hardness Test is a powerful tool in the realm of materials science and engineering. Its ability to accurately measure hardness across a broad spectrum of materials, its simplicity, and its repeatability have made it an indispensable method for understanding the properties of materials.

floor scuff remover tool

The hardness of a material can be determined based on Moh’s scale of hardness, which ranks a material based on a list of standard materials with known hardness. The hardness of the material is ranked on the scale between the material it just scratches and the material that it fails to scratch. Moh's Scale of hardness. Indentation testingThe Vickers hardness test. Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to the material’s surface, creating a square-shaped indentation. . Hardness testing is a fundamental practice in materials science and .

Department of Materials Science and Engineering, African University of Science and Technology, Abuja. . To determine the hardness of the given Specimen using Vickers hardness test.The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. . Vickers Hardness Test. Uses a diamond pyramid indenter pressed into the material. The size of the indentation determines the hardness. Pros: .For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area or depth of the indentation indicates the hardness. In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below).

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work.The indentor is applied to the test material under a load of 3000kg. The surface area of the indentation is then measured to derive the hardness, HB, of the material. Brinell testing is not suitable for very hard materials since the hardness of .

vickers hardness test manual

Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. The Significance of Vickers Hardness in Materials Science. Material Characterization: Vickers hardness testing is a valuable tool for characterizing materials, aiding in the selection of materials for specific applications. Quality Control: It plays a crucial role in industries such as automotive and aerospace by ensuring that manufactured . The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test. The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. The . Hardness evaluation is a critical aspect of material testing, providing insights into a material's resistance to deformation and wear. Among the various methods employed for hardness testing, the Vickers test stands out for its precision and versatility.. The Vickers test, developed by George E. Sandland and Robert L. Smith in 1921, utilizes a pyramidal diamond .

Microhardness testing is a crucial technique in materials science and engineering, allowing us to assess the hardness of small and delicate materials at a microscale. . The Vickers Hardness Test: The Vickers Hardness Test involves pressing a pyramid-shaped indenter with a precisely known load into the material's surface. The indenter .

rockwell hardness tester procedure pdf

Resultado da Mystery Inc. teammates Shaggy, Scooby, Velma, Daphne and Fred have creepy adventures and new mysteries to solve. Always meeting some new .

vickers hardness test material science|vickers hardness test procedure pdf